Linoleylethanolamide is a novel and potent endocannabinoid agent that acts by binding to TRPV1 (Ki = 5.60 uM), increasing ERK phosphorylation and AP-1 dependent transcription in CB-receptor in an independent manner.

Physicochemical Properties

| Molecular Formula | C20H37NO2 |

| Molecular Weight | 323.51328 |

| Exact Mass | 323.282 |

| Elemental Analysis | C, 74.25; H, 11.53; N, 4.33; O, 9.89 |

| CAS # | 68171-52-8 |

| Related CAS # | 68171-52-8 |

| PubChem CID | 5283446 |

| Appearance | Light yellow to light brown ointment |

| Density | 0.9±0.1 g/cm3 |

| Boiling Point | 499.1±38.0 °C at 760 mmHg |

| Flash Point | 255.6±26.8 °C |

| Vapour Pressure | 0.0±2.9 mmHg at 25°C |

| Index of Refraction | 1.484 |

| LogP | 5.84 |

| Hydrogen Bond Donor Count | 2 |

| Hydrogen Bond Acceptor Count | 2 |

| Rotatable Bond Count | 16 |

| Heavy Atom Count | 23 |

| Complexity | 311 |

| Defined Atom Stereocenter Count | 0 |

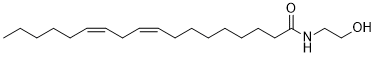

| SMILES | CCCCC/C=C\C/C=C\CCCCCCCC(NCCO)=O |

| InChi Key | KQXDGUVSAAQARU-HZJYTTRNSA-N |

| InChi Code | InChI=1S/C20H37NO2/c1-2-3-4-5-6-7-8-9-10-11-12-13-14-15-16-17-20(23)21-18-19-22/h6-7,9-10,22H,2-5,8,11-19H2,1H3,(H,21,23)/b7-6-,10-9- |

| Chemical Name | (9Z,12Z)-N-(2-hydroxyethyl)octadeca-9,12-dienamide |

| Synonyms | Linoleylethanolamide; Linoleoyl Ethanolamide; Linoleamide MEA |

| HS Tariff Code | 2934.99.03.00 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | Cannabinoid receptors of type-1(CB1/CB2) receptors |

| ln Vitro | Linoleoyl ethanolamide competitively prevents anandamide from being hydrolyzed and may have an effect on controlling how much food is consumed by deliberately extending the time between meals and feeding[3]. |

| ln Vivo | Linoleoyl ethanolamide (0.1 mg-0.2 mg; challenged by painting the inner and outer surfaces of both sides of their ears) ethanolamide reduces DNFB-induced ear swelling in BALB/c mice[3]. |

| Enzyme Assay | Several analogues of the endogenous cannabinoid receptor ligand arachidonylethanolamide (anandamide) were synthesized and evaluated in order to study (a) the structural requirements for high-affinity binding to the CB1 and CB2 cannabinoid receptors and (b) their hydrolytic stability toward anandamide amidase. The series reported here was aimed at exploring structure-activity relationships (SAR) primarily with regard to stereoelectronic requirements of ethanolamido headgroup for interaction with the cannabinoid receptor active site. Receptor affinities, reported as Ki values, were obtained by a standard receptor binding assay using [3H]CP-55,940 as the radioligand, while stability toward the amidase was evaluated by comparing the Ki of each analogue in the presence and absence of phenylmethanesulfonyl fluoride (PMSF), a serine protease blocker and inhibitor of anandamide amidase. Introduction of a methyl group in the 1'- and 2'-positions or substitution of the ethanolamido headgroup with a butylamido group gave analogues with vastly improved biochemical stability. This is accomplished in some cases with increased receptor affinity. Conversely, oxazolyl and methyloxazolyl headgroups led to low-affinity analogues. Substitution of the hydroxyl group with electronegative substituents such as fluoro, chloro, allyl, and propargyl groups significantly increased receptor affinity but did not influence the biochemical stability. The 2'-chloro analogue of anandamide was found to have the highest affinity for CB1. Additionally, reversing the positions of the carbonyl and NH in the amido group produces retro-anandamides possessing considerably higher metabolic stability. Replacement of the arachidonyl tail with oleyl or linoleyl results in analogues with low affinities for both receptors. All of the analogues in this study showed high selectivity for the CB1 receptor over the peripheral CB2 receptor. The most potent analogues were tested for their ability to stimulate the binding of [35S]GTPgammaS to G-proteins and were shown to be potent cannabimimetic agonists. The results are discussed in terms of pharmacophoric features affecting receptor affinity and enzymatic stability.[2] |

| Cell Assay | Linoleoyl ethanolamide has been showed to serve as a new and additional class of endogenous signaling molecule and exhibited a variety of biological activities in cells and tissues. [1] |

| Animal Protocol | Ischemic stroke is a significant health problem affecting over 6 million people in the United States alone. In addition to surgical and thrombolytic therapeutic strategies for stroke, neuroprotective therapies may offer additional benefit. N-acylethanolamines (NAEs) are signaling lipids whose synthesis is upregulated in response to ischemia, suggesting that they may be neuroprotective. To date only three NAEs, arachidonylethanolamide (NAE 20:4), palmitoylethanolamide (NAE 16:0) and oleoylethanolamide (NAE 18:1) have shown to exert neuroprotective effect in animal models for stroke. Here, we describe neuroprotective effects of the hitherto uncharacterized NAEs, lauroylethanolamide (NAE 12:0) and linoleoylethanolamide (NAE 18:2) in a middle cerebral artery occlusion model of stroke. Pretreatment with NAE 18:2 prior to ischemia/reperfusion (I/R) injury resulted in both significantly reduced cortical infarct volume and improved functional outcome as determined using the neurological deficit score. NAE 12:0 improved neurological deficits without a significant reduction lesion size. Our results suggest that NAEs, as a whole, provide neuroprotection during I/R injury and may have therapeutic benefit when used as complementary treatment with other therapies to improve stroke outcome.[3] |

| References |

[1]. Synthesis of linoleoyl ethanolamide. J Oleo Sci. 2013;62(6):427-433. [2]. Novel analogues of arachidonylethanolamide (anandamide): affinities for the CB1 and CB2 cannabinoid receptors and metabolic stability. J Med Chem. 1998;41(27):5353-5361. [3]. Neurosci Lett. 2011 Apr 4;492(3):134-8. |

| Additional Infomation |

Linoleoyl ethanolamide is an N-acylethanolamine 18:2 that is the ethanolamide of linoleic acid. It has a role as an EC 3.5.1.99 (fatty acid amide hydrolase) inhibitor. It is functionally related to a linoleic acid. Linoleoyl ethanolamide has been reported in Glycine max, Zea mays, and other organisms with data available. |

Solubility Data

| Solubility (In Vitro) | May dissolve in DMSO (in most cases), if not, try other solvents such as H2O, Ethanol, or DMF with a minute amount of products to avoid loss of samples |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 3.0911 mL | 15.4555 mL | 30.9109 mL | |

| 5 mM | 0.6182 mL | 3.0911 mL | 6.1822 mL | |

| 10 mM | 0.3091 mL | 1.5455 mL | 3.0911 mL |