Physicochemical Properties

| Molecular Formula | C3H7N3O2 |

| Molecular Weight | 117.12 |

| Exact Mass | 117.053 |

| Elemental Analysis | C, 30.77; H, 6.03; N, 35.88; O, 27.32 |

| CAS # | 352-97-6 |

| PubChem CID | 763 |

| Appearance | Typically exists as white to off-white solids at room temperature |

| Density | 1.6±0.1 g/cm3 |

| Boiling Point | 294.2±42.0 °C at 760 mmHg |

| Melting Point | 300 °C(lit.) |

| Flash Point | 131.7±27.9 °C |

| Vapour Pressure | 0.0±1.3 mmHg at 25°C |

| Index of Refraction | 1.596 |

| LogP | -1.85 |

| Hydrogen Bond Donor Count | 3 |

| Hydrogen Bond Acceptor Count | 3 |

| Rotatable Bond Count | 2 |

| Heavy Atom Count | 8 |

| Complexity | 116 |

| Defined Atom Stereocenter Count | 0 |

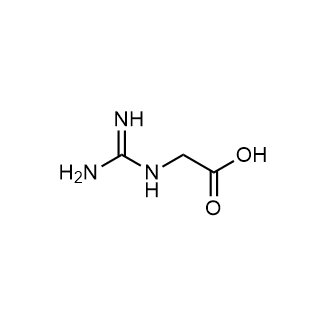

| SMILES | O([H])C(C([H])([H])/N=C(\N([H])[H])/N([H])[H])=O |

| InChi Key | BPMFZUMJYQTVII-UHFFFAOYSA-N |

| InChi Code | InChI=1S/C3H7N3O2/c4-3(5)6-1-2(7)8/h1H2,(H,7,8)(H4,4,5,6) |

| Chemical Name | 2-(diaminomethylideneamino)acetic acid |

| Synonyms | AI3 17119; AI3-17119; glycocyamine; 352-97-6; guanidinoacetic acid; Guanidineacetic acid; 2-Guanidinoacetic acid; Guanidoacetic acid; N-amidinoglycine; Betacyamine; Glycocyamine |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | Precursor for creatine |

| ln Vitro |

GAA Affects Myogenic Differentiation of Myoblast in Dose-Dependent Manner. GAA Modulates Myogenesis through MicroRNA Regulatory Network Guanidinoacetic acid (GAA), an amino acid derivative that is endogenous to animal tissues including muscle and nerve, has been reported to enhance muscular performance. MicroRNA (miRNA) is a post-transcriptional regulator that plays a key role in nutrient-mediated myogenesis. However, the effects of GAA on myogenic differentiation and skeletal muscle growth, and the potential regulatory mechanisms of miRNA in these processes have not been elucidated. In this study, we investigated the effects of GAA on proliferation, differentiation, and growth in C2C12 cells and mice. The results showed that GAA markedly inhibited the proliferation of myoblasts, along with the down-regulation of cyclin D1 (CCND1) and cyclin dependent kinase 4 (CDK4) mRNA expression, and the upregulation of cyclin dependent kinase inhibitor 1A (P21) mRNA expression. We also demonstrated that GAA treatment stimulated myogenic differentiation 1 (MyoD) and myogenin (MyoG) mRNA expression, resulting in an increase in the myotube fusion rate. Meanwhile, GAA supplementation promoted myotube growth through increase in total myosin heavy chain (MyHC) protein level, myotubes thickness and gastrocnemius muscle cross-sectional area. Furthermore, small RNA sequencing revealed that a total of eight miRNAs, including miR-133a-3p and miR-1a-3p cluster, showed differential expression after GAA supplementation. To further study the function of miR-133a-3p and miR-1a-3p in GAA-induced skeletal muscle growth, we transfected miR-133a-3p and miR-1a-3p mimics into myotube, which also induced muscle growth. Through bioinformatics and a dual-luciferase reporter system, the target genes of miR-133a-3p and miR-1a-3p were determined. These two miRNAs were shown to modulate the Akt/mTOR/S6K signaling pathway by restraining target gene expression. Taken together, these findings suggest that GAA supplementation can promote myoblast differentiation and skeletal muscle growth through miR-133a-3p- and miR-1a-3p-induced activation of the AKT/mTOR/S6K signaling pathway[2]. |

| ln Vivo | Guanidino acetic acid (GAA) is synthesized in the liver and kidney from Arg and Gly and subsequently methylated by S-adenosylmethionine to form creatine. Four bioassays were carried out to determine the capacity of GAA to serve as a dietary replacement for Arg for growing chicks. Broiler chicks were fed Arg-deficient dextrose-casein (0.88% Arg) or corn-corn coproduct-soybean meal (1.0% Arg) basal diets during 9-d battery feeding trials involving 5 pens of 4 chicks per treatment. The dextrose-casein diet was shown to be markedly deficient in Arg as both weight gain and G:F increased (P < 0.01) due to addition of Arg, GAA, or creatine. The optimal level of added GAA was 0.12% of the diet, but this level of GAA or 1.0% creatine-H(2)O did not improve growth performance when added to an Arg-adequate diet. A second assay confirmed this level of optimal Arg in a 2 × 2 factorial arrangement of l-Arg and GAA supplementation. Using a practical-type diet based on corn, corn gluten meal, distillers dried grains with solubles, and soybean meal, similar improvements (P < 0.05) in G:F resulted from addition of 0.25% Arg, 0.12% GAA, or 0.15% creatine·H(2)O. These results demonstrate that 0.12% supplemental GAA, like creatine, produces consistent growth responses in young chicks fed Arg-deficient diets. To provide further evidence of the capacity for GAA to serve as a dietary Arg replacement, the dextrose-casein diet was supplemented with 7 graded doses of Arg in the absence or presence of 0.12% GAA (14 total diets). Quadratic (P < 0.01) responses in weight gain and G:F responses to supplemental Arg were observed. Similar supplemental Arg requirements were estimated in the absence and presence of 0.12% GAA, but GAA elicited a greater improvement (P < 0.05) in G:F when added to Arg-deficient, compared with Arg-adequate, diets. Collectively, these data indicate that GAA can be used as an efficacious replacement for dietary Arg for young chicks[1]. |

| Cell Assay |

The murine skeletal muscle cell line C2C12 was cultured in growth medium (GM) that contained high-glucose DMEM, supplemented with 10% fetal bovine serum, 100,000 units/L penicillin sodium, and 100 mg/L streptomycin sulfate at 37 °C in a humidified atmosphere containing 5% CO2. The C2C12 myoblasts were induced with differentiation medium (DM) containing high-glucose DMEM and 2% horse serum for 8 days. GAA was soluble in GM or DM at a final concentration of 20 mmol/L. Rapamycin (Rap) was diluted in DMSO at a final concentration of 100 nmol/L; the final concentration of DMSO was less than 0.1% in the culture[2]. Cell Proliferation Ratio Assay.[2] C2C12 cells proliferation ratio was detected by Cell Counting Kit-8 (CCK-8) and EdU Cell Proliferation Assay Kit. C2C12 cells were seeded in a 96-well cell culture plate and maintained in GM, which contained 0 mM, 5 mM, 10 mM or 20 mM GAA for 48 h; the medium was changed every 12 h. For CCK-8, 10 μL CCk-8 reagent was added to the medium, after 1 h, optical density was measured at 450 nm. For EdU cell proliferation assay, cells were treated with GAA of different concentrations, and when the cells reached approximately 80% confluence, 10 μM EdU was added to the medium and incubated for 2 h. EdU staining was done according to the manufacturer’s instructions; cell nucleus was stained by DAPI. Stained cells were imaged by Olympus IX53 microscope. Western Blot Assay.[2] Briefly, the cells were seeded in a six-well cell culture plate. After differentiation for 4 days, cells were incubated with Rap or GAA as described for 48 h. The cells were then rinsed in PBS three times and lysed in 200 μL RIPA lysis buffer that contained 1 mM PMSF and 0.02% Protease phosphatase inhibitors. For tissues, 25 mg gastrocnemius muscle was homogenized in 500 μL RIPA lysis buffer that contained 1 mM PMSF and 0.02% Protease phosphatase inhibitors. Afterwards, the homogenized liquids were shocked for 30 min at 4 °C, and the insoluble matter was removed from the suspension by 12,000× g centrifugation for 15 min. The total protein concentration was quantified using BCA protein assays. After aliquots 50 μg protein suspension was separated by 10% sodium dodecyl sulfate (SDS) polyacrylamide electrophoresis gels, the proteins were transferred to polyvinylidene fluoride (PVDF) membranes using the Trans-Blot Turbo transfer system, and then blocked with 5% (w/v) non-fat dry milk in Tris-buffered saline that contained 0.1% Tween 20 for 2 h at room temperature. The PVDF membranes were then incubated with the indicated antibodies at 4 °C overnight, followed by incubation with the secondary antibody for 1 h at room temperature. Protein expression was measured using a ChemiDoc MP Imaging System and normalized to tubulin expression. |

| Animal Protocol |

Animals and Muscle Collection[2] The Kunming male mice (n = 30) at 3 weeks of age were purchased from DASHUO Medical Laboratory Animal Center. The mice were given free access to food and water under constant 12 h light and 12 h dark cycle at a temperature of 23 °C ± 3 °C and relative humidity of 70% ± 10% throughout experimental period. After one week of acclimatization, the mice were randomly divided into three groups (n = 10 in each group) and supplemented with different concentrations of GAA (0%, 1% and 2%), dissolved in drinking water for 8 weeks. At the end of the experiment, serum was collected and the gastrocnemius muscle was taken for further testing. The serum was stored at −80 °C, the muscle stored in liquid nitrogen. |

| ADME/Pharmacokinetics |

Metabolism / Metabolites Guanidino acetic acid (GAA) is synthesized in the liver and kidney from Arg and Gly and subsequently methylated by S-adenosylmethionine to form creatine. The conversion of guaniodacetate to creatinine in the liver causes a depletion of methyl groups. This causes homocysteine levels to rise, which has been shown to produce cardiovascular and skeletal problems. |

| Toxicity/Toxicokinetics |

Toxicity Summary Uremic toxins such as guanidinoacetic acid are actively transported into the kidneys via organic ion transporters (especially OAT3). Increased levels of uremic toxins can stimulate the production of reactive oxygen species. This seems to be mediated by the direct binding or inhibition by uremic toxins of the enzyme NADPH oxidase (especially NOX4 which is abundant in the kidneys and heart) (A7868). Reactive oxygen species can induce several different DNA methyltransferases (DNMTs) which are involved in the silencing of a protein known as KLOTHO. KLOTHO has been identified as having important roles in anti-aging, mineral metabolism, and vitamin D metabolism. A number of studies have indicated that KLOTHO mRNA and protein levels are reduced during acute or chronic kidney diseases in response to high local levels of reactive oxygen species (A7869) |

| References |

[1]. Dietary guanidino acetic acid is an efficacious replacement for arginine for young chicks. Poult Sci. 2013 Jan;92(1):171-7. |

| Additional Infomation |

Guanidinoacetic acid is the N-amidino derivative of glycine. It has a role as a human metabolite, a mouse metabolite, a nutraceutical, a rat metabolite and a bacterial metabolite. It is a conjugate acid of a guanidinoacetate. It is a tautomer of a guanidinoacetic acid zwitterion. Glycocyamine has been reported in Citrus reticulata, Prunus persica, and other organisms with data available. Glycocyamine is a naturally-occurring derivative of glycine and a metabolic precursor of creatine. Glycocyamine, also known as guanidinoacetic acid (GAA), is catalyzed by guanidinoacetate N-methyltransferase to form creatine. Creatine, in phosphate form, helps supply energy to muscle cells for contraction. After intense effort, when adenosine triphosphate (ATP) deposits are depleted, creatine phosphate donates phosphate groups toward the fast synthesis of ATP. Dietary supplementation with GAA may improve muscle wasting associated with cancer and other chronic diseases. Guanidinoacetic acid is a uremic toxin. Uremic toxins can be subdivided into three major groups based upon their chemical and physical characteristics: 1) small, water-soluble, non-protein-bound compounds, such as urea; 2) small, lipid-soluble and/or protein-bound compounds, such as the phenols and 3) larger so-called middle-molecules, such as beta2-microglobulin. Chronic exposure of uremic toxins can lead to a number of conditions including renal damage, chronic kidney disease and cardiovascular disease. Guanidoacetic acid is a metabolite in the Urea cycle and metabolism of amino groups, and in the metabolic pathways of several amino acids. This includes glycine, serine, threonine, arginine and proline metabolism. Guanidinoacetic acid is also a precursor of creatine, an essential substrate for muscle energy metabolism. |

Solubility Data

| Solubility (In Vitro) |

1M HCl : 50 mg/mL (~426.95 mM) H2O : ~5 mg/mL (~42.69 mM) |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 8.5383 mL | 42.6913 mL | 85.3825 mL | |

| 5 mM | 1.7077 mL | 8.5383 mL | 17.0765 mL | |

| 10 mM | 0.8538 mL | 4.2691 mL | 8.5383 mL |