Physicochemical Properties

| Molecular Weight | 435.26 |

| Exact Mass | 434.043 |

| CAS # | 2804026-81-9 |

| PubChem CID | 166642475 |

| Appearance | Typically exists as solid at room temperature |

| LogP | 3.3 |

| Hydrogen Bond Donor Count | 1 |

| Hydrogen Bond Acceptor Count | 5 |

| Rotatable Bond Count | 2 |

| Heavy Atom Count | 29 |

| Complexity | 669 |

| Defined Atom Stereocenter Count | 2 |

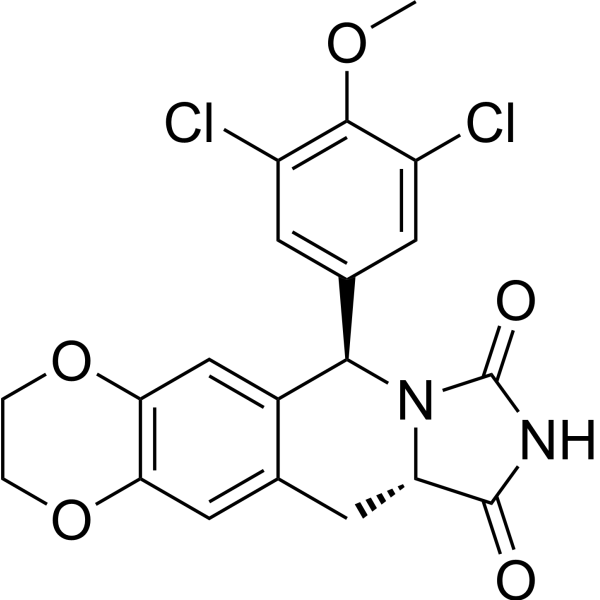

| SMILES | COC1=C(C=C(C=C1Cl)[C@@H]2C3=CC4=C(C=C3C[C@@H]5N2C(=O)NC5=O)OCCO4)Cl |

| InChi Key | GANPPQNYXDZLNS-WMLDXEAASA-N |

| InChi Code | InChI=1S/C20H16Cl2N2O5/c1-27-18-12(21)4-10(5-13(18)22)17-11-8-16-15(28-2-3-29-16)7-9(11)6-14-19(25)23-20(26)24(14)17/h4-5,7-8,14,17H,2-3,6H2,1H3,(H,23,25,26)/t14-,17+/m0/s1 |

| Chemical Name | (11R,16S)-11-(3,5-dichloro-4-methoxyphenyl)-4,7-dioxa-12,14-diazatetracyclo[8.7.0.03,8.012,16]heptadeca-1,3(8),9-triene-13,15-dione |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| ln Vitro | Tubulin polymerization-IN-41 (compound C3) demonstrates noteworthy anti-proliferative action against K562, MCF-7, HT29, and HCT116 cells, with IC50 values of 6.3 nM, 9.2 nM, 8.3 nM, and 8.7 nM, respectively. Furthermore, Tubulin polymerization-IN-41 shown noteworthy efficacy against A549 cells and MCF-7 cells resistant to paclitaxel [1]. Compound C3, or tubulin polymerization-IN-41, exhibits a concentration-dependent upregulation of detyrosinated-α-tubulin (DeY-α-tubulin) expression and a downregulation of acetyl-α-tubulin (Ac-α-tubulin) expression [1]. In a concentration-dependent manner, tubulin polymerization-IN-41 (compound C3; 5–20 nM; 24 h) can cause MCF-7 cell death and block cancer cells at G2/M [1]. Compound C3, tubulin polymerization-IN-41, decreases Ser216 phosphorylation, which in turn causes cdc2 Tyr15 dephosphorylation and Thr161 phosphorylation, which in turn causes the cdc2/cyclin B1 complex to be activated [1]. MCF-7 cells tubulin polymerization-IN-41 at 5 nM, 10 nM, and 20 nM during 24 hours. |

| ln Vivo | Tubulin polymerization-IN-41 (compound C3) shown notable dose-dependent tumor growth inhibitory activity throughout medication therapy without causing weight loss [1]. Tubulin polymerization-IN-41 is administered intraperitoneally (i.p.) once every two days for 21 consecutive days. |

| Cell Assay |

Cell Cycle Analysis[1] Cell Types: MCF-7 cells Tested Concentrations: 5 nM, 10 nM, 20 nM Incubation Duration: 24 h Experimental Results: Could arrest cancer cells in the G2/M phase. Apoptosis Analysis[1] Cell Types: MCF-7 cells Tested Concentrations: 5 nM, 10 nM, 20 nM Incubation Duration: 24 h Experimental Results: Induced MCF-7 cells apoptosis. Western Blot Analysis[1] Cell Types: MCF-7 cells Tested Concentrations: 5 nM, 10 nM, 20 nM Incubation Duration: 24 h Experimental Results: Induced cdc25c activation. |

| Animal Protocol |

Animal/Disease Models: Fiveweeks old female athymic nude mice injected with MCF-7 cells[1] Doses: 5, 10, and 20 mg/kg Route of Administration: intraperitoneal (ip)injection; every two days; for 21 days Experimental Results: demonstrated the significant potency of tumor growth inhibition in a dose dependence without weight loss in the drug-treated period. |

| References |

[1]. Discovery of Novel N-Heterocyclic-Fused Deoxypodophyllotoxin Analogues as Tubulin Polymerization Inhibitors Targeting the Colchicine-Binding Site for Cancer Treatment. J Med Chem. 2022 Dec 22;65(24):16774-16800. |

Solubility Data

| Solubility (In Vitro) | May dissolve in DMSO (in most cases), if not, try other solvents such as H2O, Ethanol, or DMF with a minute amount of products to avoid loss of samples |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 2.2975 mL | 11.4874 mL | 22.9748 mL | |

| 5 mM | 0.4595 mL | 2.2975 mL | 4.5950 mL | |

| 10 mM | 0.2297 mL | 1.1487 mL | 2.2975 mL |