Physicochemical Properties

| Molecular Formula | C24H36CLN3O2 |

| Molecular Weight | 434.01 |

| Exact Mass | 433.25 |

| CAS # | 1216621-00-9 |

| PubChem CID | 56972178 |

| Appearance | Typically exists as solid at room temperature |

| LogP | 4.832 |

| Hydrogen Bond Donor Count | 2 |

| Hydrogen Bond Acceptor Count | 3 |

| Rotatable Bond Count | 5 |

| Heavy Atom Count | 30 |

| Complexity | 597 |

| Defined Atom Stereocenter Count | 0 |

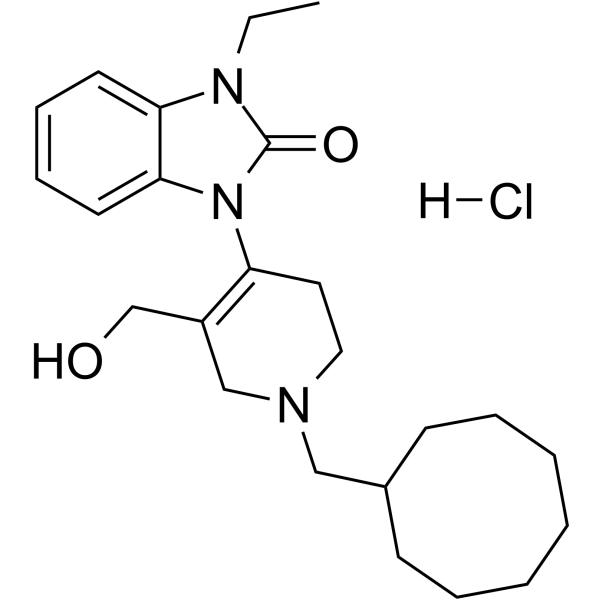

| SMILES | CCN1C2=CC=CC=C2N(C3=C(CN(CC3)CC4CCCCCCC4)CO)C1=O.Cl |

| InChi Key | YEVMLMQAMCKVSC-UHFFFAOYSA-N |

| InChi Code | InChI=1S/C24H35N3O2.ClH/c1-2-26-22-12-8-9-13-23(22)27(24(26)29)21-14-15-25(17-20(21)18-28)16-19-10-6-4-3-5-7-11-19;/h8-9,12-13,19,28H,2-7,10-11,14-18H2,1H3;1H |

| Chemical Name | 1-[1-(cyclooctylmethyl)-5-(hydroxymethyl)-3,6-dihydro-2H-pyridin-4-yl]-3-ethylbenzimidazol-2-one;hydrochloride |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | pKi: 8.65 (NOP receptor); 6.60 (μ-opioid receptor); 6.14 (κ-opioid receptor); < 5 (δ-opioid receptor)[1] |

| ln Vitro | In the range of 3-300 nM, trap-101 hydrochloride (3, 30, and 300 nM) causes a concentration-dependent rightward shift of the concentration-response curve to N/OFQ without changing the peak response to the agonist. Up to 10 μM, trap-101 hydrochloride is inert per se. Trap101's receptor binding affinities (pKi values) at traditional opioid receptors expressed in CHO cell membranes, recombinant human NOP receptors, and μ-, κ-, and δ-opioid receptors are 6.14, 8.65, 6.60, and less than five, respectively[1]. |

| ln Vivo | In addition to causing a delayed increase in immobility time in the bar test at 30 mg/kg, trap-101 hydrochloride (10–30 mg/kg; identified after 90 min) alters motor activity in naïve rats. It also increases stepping activity and rotarod performance at 10 mg/kg and decreases both at 30 mg/kg[1]. 6-OHDA lesioning results in decreased motor function overall and motor asymmetry that mostly affects the contralateral paw. In hemiparkinsonian rats, intraperitoneal injection of Trap-101 hydrochloride (10–30 mg/kg; 90 min detection) ameliorates akinesia/bradykinesia and enhances gait overall; it is efficacious at 1 mg/kg and does not increase motor deficit at 30 mg/kg[1]. |

| Animal Protocol |

Animal/Disease Models: 6-OHDA hemilesioned rats[1] Doses: 10-30 mg/kg Route of Administration: intraperitoneal (ip) injection; 10-30 mg/kg; detected after 90 min Experimental Results: Attenuated parkinsonian-like motor deficits in rat. |

| References |

[1]. The novel nociceptin/orphanin FQ receptor antagonist Trap-101 alleviates experimental parkinsonism through inhibition of the nigro-thalamic pathway: positive interaction with L-DOPA. J Neurochem. 2008 Dec;107(6):1683-96. |

Solubility Data

| Solubility (In Vitro) | May dissolve in DMSO (in most cases), if not, try other solvents such as H2O, Ethanol, or DMF with a minute amount of products to avoid loss of samples |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 2.3041 mL | 11.5205 mL | 23.0409 mL | |

| 5 mM | 0.4608 mL | 2.3041 mL | 4.6082 mL | |

| 10 mM | 0.2304 mL | 1.1520 mL | 2.3041 mL |