Physicochemical Properties

| Molecular Formula | C11H9CLO5 |

| Molecular Weight | 256.64 |

| Exact Mass | 256.013 |

| CAS # | 19165-63-0 |

| PubChem CID | 107911 |

| Appearance | White to light yellow solid powder |

| Density | 1.5±0.1 g/cm3 |

| Boiling Point | 521.4±50.0 °C at 760 mmHg |

| Flash Point | 269.1±30.1 °C |

| Vapour Pressure | 0.0±1.4 mmHg at 25°C |

| Index of Refraction | 1.620 |

| LogP | 3.81 |

| Hydrogen Bond Donor Count | 2 |

| Hydrogen Bond Acceptor Count | 5 |

| Rotatable Bond Count | 1 |

| Heavy Atom Count | 17 |

| Complexity | 345 |

| Defined Atom Stereocenter Count | 1 |

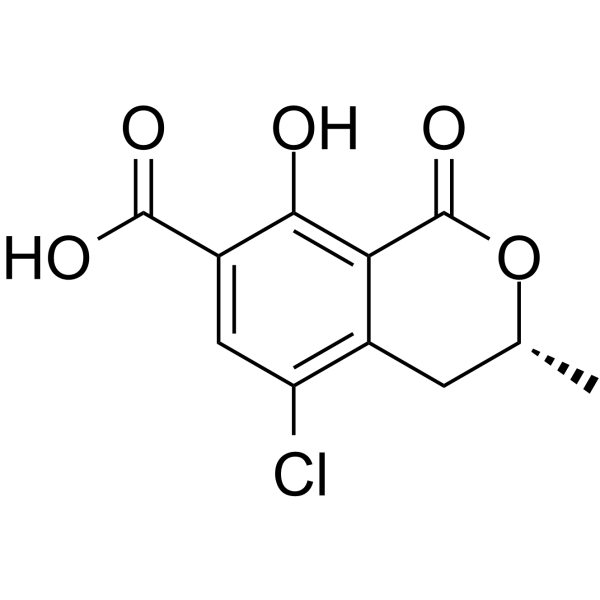

| SMILES | C[C@@H]1CC2=C(C=C(C(=C2C(=O)O1)O)C(=O)O)Cl |

| InChi Key | OSFWJKYWJMZKSM-SCSAIBSYSA-N |

| InChi Code | InChI=1S/C11H9ClO5/c1-4-2-5-7(12)3-6(10(14)15)9(13)8(5)11(16)17-4/h3-4,13H,2H2,1H3,(H,14,15)/t4-/m1/s1 |

| Chemical Name | (3R)-5-chloro-8-hydroxy-3-methyl-1-oxo-3,4-dihydroisochromene-7-carboxylic acid |

| Synonyms | Ochratoxin alpha; alpha-Ochratoxin; 19165-63-0; UNII-EB6BD1257Y; EB6BD1257Y; (R)-ochratoxin alpha; (-)-ochratoxin alpha; (3R)-5-chloro-8-hydroxy-3-methyl-1-oxo-3,4-dihydroisochromene-7-carboxylic acid; |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month Note: Please store this product in a sealed and protected environment (e.g. under nitrogen), avoid exposure to moisture. |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | Degradation product of Ochratoxin A |

| ln Vitro |

Specifically, it has previously been demonstrated that thermolysin and bovine carboxypeptidase A (CPA) may hydrolyze OTA into OTα and phenylalanine[1]. Ochratoxin A (OTA), a mycotoxin that is of utmost concern in food and feed safety, is produced by fungal species that mainly belong to the Aspergillus and Penicillium genera. The development of mitigation strategies to reduce OTA content along the supply chains is key to ensuring safer production of food and feed. Enzyme-based strategies are among the most promising methods due to their specificity, efficacy, and multi-situ applicability. In particular, some enzymes are already known for hydrolyzing OTA into ochratoxin alpha (OTα) and phenylalanine (Phe), eventually resulting in detoxification action. Therefore, the discovery of novel OTA hydrolyzing enzymes, along with the advancement of an innovative approach for their identification, could provide a broader basis to develop more effective mitigating strategies in the future. In the present study, a hybrid in silico/in vitro workflow coupling virtual screening with enzymatic assays was applied in order to identify novel OTA hydrolyzing enzymes. Among the various hits, porcine carboxypeptidase B was identified for the first time as an effective OTA hydrolyzing enzyme. The successful experimental endorsement of findings of the workflow confirms that the presented strategy is suitable for identifying novel OTA hydrolyzing enzymes, and it might be relevant for the discovery of other mycotoxin- mitigating enzymes.[1] The mycotoxin ochratoxin A is a secondary metabolite occurring in a wide range of commodities. During the exposure of ochratoxin A to white and blue light, a cleavage between the carbon atom C-14 and the nitrogen atom was described. As a reaction product, the new compound ochratoxin alpha (OTα) amide has been proposed based on mass spectrometry (MS) experiments. In the following study, we observed that this compound is also formed at high temperatures such as used for example during coffee roasting and therefore represents a further thermal ochratoxin A degradation product. To confirm the structure of ochratoxin alpha (OTα) amide, the compound was prepared in large scale and complete structure elucidation via nuclear magnetic resonance (NMR) and MS was performed. Additionally, first studies on the toxicity of ochratoxin alpha (OTα)α amide were performed using immortalized human kidney epithelial (IHKE) cells, a cell line known to be sensitive against ochratoxin A with an IC50 value of 0.5 μM. Using this system, ochratoxin alpha (OTα) amide revealed no cytotoxicity up to concentrations of 50 μM. Thus, these results propose that the thermal degradation of ochratoxin A to ochratoxin alpha (OTα) amide might be a detoxification process. Finally, we present a sample preparation and a HPLC-tandem mass spectrometry (HPLC-MS/MS) method for the analysis of ochratoxin alpha (OTα) amide in extrudates and checked its formation during the extrusion of artificially contaminated wheat grits at 150 and 180 °C, whereas no ochratoxin alpha (OTα) amide was detectable under these conditions [2]. |

| Enzyme Assay |

Estimation of OTA Hydrolyzing Activity [1] Neprilysin (EC: 3.4.24.11; 10UG), Matrix metalloproteinase 12 (MMP-12; EC: 3.4.24.65;10UG), Carboxypeptidase B (CPB; EC: 3.4.17.2; 1MG), Urokinase (EC: 3.4.21.73;10KU), and beta-site APP cleaving enzyme 1 (BACE-1; EC: 3.4.23.46; 50UG) were used. Neprilysin, CPB and Urokinase were reconstituted in 100 µL, 200 µL, and 200 µL phosphate buffered saline buffer pH 7.4, respectively. MMP-12 was diluted 1:10 in phosphate buffered saline buffer pH 7.4 to a final volume of 100 µL. All content of BACE-1 was used directly, as supplied by Sigma in 20 mM Hepes, pH 7.4, containing 125 mM sodium chloride. Enzymatic assay was set up in 200 µL of reaction mixture, which contained 50 µL of reconstituted enzyme preparation, 100 µL of 400 ng/mL Ochratoxin A (prepared in the respective reaction buffer), and 50 µL of reaction buffer. The final concentration of OTA in each reaction mixture was 200 ng/mL. For BACE-1, 100 mM MES pH 4.5 was used as reaction buffer and for the other tested enzymes 100 mM sodium phosphate buffer pH 7.5. The final amount of enzyme in the 200 µL reaction mixture was 5 µg for Neprilysin, 5 µg for MMP-12, 665 µg for CPB, 2500 IU (as specified by supplier) for Urokinase, and 50 µg of BACE-1. Each reaction mixture was incubated at 37 °C for 180 min. along with separate negative reaction control, which contains OTA 200 ng/mL without enzyme. The treatment time and temperature were was scaled to 180 minutes and 37 °C to provide conditions that are meaningful for a practical implementation of the method meant in this study. A separate reaction was performed with 2 mg of Carboxypeptidase A (500UN) in 200 µL reaction mix as a positive control. Each reaction was stopped adding 200 µL of acetonitrile at stored for 10 min. at 4 °C followed by centrifugation at 20,000 g for 10 min. at 4 °C. Afterward, 2 µL of supernatant were analyzed by HPLC-MS (Agilent 1290 Infinity II coupled to Sciex QTRAP 6500+ ESI, column Phenomenex Kinetex 2.6µm EVO C18 100 Å, 150x2.1 mm) to determine the concentration of OTA and its hydrolyzed product OTα. Three transitions of OTA (m/z 402 → 358+167+211) and OTα (m/z 255 → 211+167+123) were monitored to detect each compound, the transitions m/z 402 → 167 and m/z 255 → 167 were used to quantify OTA and OTα, respectively. A gradient of eluent B (94.9% ACN, 5% water, 0.1% formic acid) from 20% between 0.0–0.25 min. then gradually increased to 100% between 0.25–2.0 min. and stay at 100% between 2.00-2.50 min then immediately reduced to 20% at 2.51 min to calibrate column till 3.0 min. was used, in respect to eluent A consisted of 94.9% water, 5% ACN, 0.1% formic acid. Analytical grade pure OTA and OTα were used in the setting up OTA hydrolyzing assay (including negative reaction control), as well as used as standard in the range of 100 ng/mL to 0.195 ng/mL for an estimation of disappearance of OTA and the appearance of OTα in the enzymatic reaction sample by HPLC-MS quantification (Figure S19, Supporting Material). Each sample was analyzed in duplicate, with CV below 10%. In case CV was more than 10%, the whole analysis was repeated. |

| Cell Assay |

Cytotoxicity assay (CCK-8) [2] IHKE cells were used for the cytotoxicity experiments. These cells were cultivated, as described by Tveito et al., and as previously applied by Cramer et al. (Cramer et al. 2010; Ishiyama et al. 1996; Tveito et al. 1989). The determination of the cytotoxicity was performed by a colorimetric assay using the Cell Counting Kit-8 (CCK-8) according to the manufacturer’s instructions the metabolic activity of the cells was measured. Therefore, the cells were seeded in 96-well plates. After a growth of 48 h, the cells were cultivated in a serum-free medium for 24 h in order to exclude any binding of the tested compounds to serum proteins. Then solutions of ochratoxin α amide were added to the cells in a concentration range from 0.01 nM to 50 μM (stock solution: 10 mM in methanol) and incubated for 24 h. Cells with an equal solvent concentration were incubated as control. Afterwards, the viability of the cells was measured as previously described (Cramer et al. 2010). The incubation time with the dye solution WST-8 [2-(2-methoxy-4-nitrophenyl)-3-(4-nitrophenyl)-5-(2.4-disulfophenyl)-2H-tetrazolium, monosodium salt] was changed to 45 min. This experimental setup was simultaneously done with ochratoxin alpha (OTα), ochratoxin A, and 14R-ochratoxin A for comparison. |

| References |

[1]. An In Silico Target Fishing Approach to Identify Novel Ochratoxin A Hydrolyzing Enzyme. 2020 Apr 16;12(4):258. [2]. Structure elucidation and in vitro cytotoxicity of ochratoxin α amide, a new degradation product of ochratoxin A. Mycotoxin Res. 2015 May;31(2):83-90. |

| Additional Infomation |

Ochratoxin alpha is a member of the class of isocoumarins that is 1-oxo-3,4-dihydro-2-benzopyran-7-carboxylic acid carrying additional methyl, chloro and hydroxy substituents at positions 3, 5 and 8 respectively. A non-toxic metabolite of the mycotoxin ochratoxin A. It has a role as a bacterial xenobiotic metabolite, a human urinary metabolite, a human xenobiotic metabolite and a marine xenobiotic metabolite. It is a member of isochromanes, a member of isocoumarins, an organochlorine compound, a member of phenols and a member of benzoic acids. It is a conjugate acid of an ochratoxin alpha(1-). In summary, we could show that ochratoxin α amide can also be formed during thermal treatment. Using a fast heating procedure and isolation by HPLC, ochratoxin α amide could be isolated for complete structure elucidation. First toxicity studies for ochratoxin α amide indicate that this compound is less cytotoxic compared to ochratoxin A. In addition, we successfully developed a HPLC-MS/MS method for the analysis of ochratoxin α amide in extruded wheat grits. However, so far, no ochratoxin α amide could be detected during model experiments with artificial contaminated wheat grits in combination with extrusion cooking at temperatures up to 180 °C.[2] |

Solubility Data

| Solubility (In Vitro) | DMSO: 133.33 mg/mL (519.52 mM) |

| Solubility (In Vivo) |

Solubility in Formulation 1: ≥ 4.5 mg/mL (17.53 mM) (saturation unknown) in 10% DMSO + 40% PEG300 + 5% Tween80 + 45% Saline (add these co-solvents sequentially from left to right, and one by one), clear solution. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 45.0 mg/mL clear DMSO stock solution to 400 μL PEG300 and mix evenly; then add 50 μL Tween-80 to the above solution and mix evenly; then add 450 μL normal saline to adjust the volume to 1 mL. Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH₂ O to obtain a clear solution. Solubility in Formulation 2: 4.5 mg/mL (17.53 mM) in 10% DMSO + 90% (20% SBE-β-CD in Saline) (add these co-solvents sequentially from left to right, and one by one), suspension solution; with ultrasonication. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 45.0 mg/mL clear DMSO stock solution to 900 μL of 20% SBE-β-CD physiological saline solution and mix evenly. Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Solubility in Formulation 3: ≥ 4.5 mg/mL (17.53 mM) (saturation unknown) in 10% DMSO + 90% Corn Oil (add these co-solvents sequentially from left to right, and one by one), clear solution. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 45.0 mg/mL clear DMSO stock solution to 900 μL of corn oil and mix evenly. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 3.8965 mL | 19.4825 mL | 38.9651 mL | |

| 5 mM | 0.7793 mL | 3.8965 mL | 7.7930 mL | |

| 10 mM | 0.3897 mL | 1.9483 mL | 3.8965 mL |