Physicochemical Properties

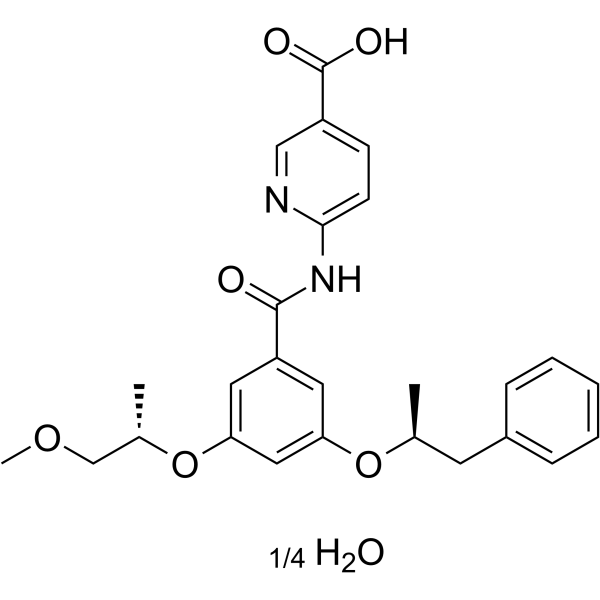

| Molecular Formula | C26H28N2O6.1/4H2O |

| Molecular Weight | 469.01 |

| Related CAS # | GKA50;851884-87-2 |

| Appearance | White to off-white solid powder |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| ln Vitro | GKA50 (0.01-100 μM; 24 hours) increases the proliferation of INS-1 cells, with EC50 values between 1 and 2 μM[2]. In INS-1 cells, treatment with GKA50 (1.2 μM+40 μM glucose; 2-4 days) decreases apoptosis caused by prolonged elevated glucose[2]. With an EC50 of 0.022 μM, GKA50 initiates the enzymatic activity of human glucokinase. With an EC50 of 0.065 μM, GKA50 increases insulin secretion in the pancreatic insulinoma cell line, INS-1. Through the regulation of glucokinase and the apoptotic protein BAD, GKA50 lessens chronically high glucose-induced apoptosis[2]. |

| ln Vivo | In an oral glucose tolerance test, GKA50 (1-30 mg/kg; po) significantly lowers glucose levels[1]. |

| Cell Assay |

Cell Proliferation Assay[2] Cell Types: INS-1 cells(starved overnight with 3 μM glucose) Tested Concentrations: 0.01-100 μM Incubation Duration: 24 hrs (hours) Experimental Results: Stimulated cell proliferation in a dose-dependent manner, with EC50 values ranging from 1 to 2 μM. |

| Animal Protocol |

Animal/Disease Models: High-fat-fed obese female Zucker (fa/fa) rats[1] Doses: 1, 3 , 10, 30 mg/kg Route of Administration: Oral administration Experimental Results: Significant percentage glucose lowering. |

| References |

[1]. Predictive blood glucose lowering efficacy by Glucokinase activators in high fat fed female Zucker rats. Br J Pharmacol. 2006 Oct;149(3):328-35. [2]. The glucokinase activator GKA50 causes an increase in cell volume and activation of volume-regulated anion channels in rat pancreatic β-cells. Mol Cell Endocrinol. 2011 Aug 6;342(1-2):48-53. [3]. Glucokinase activators: molecular tools for studying the physiology of insulin-secreting cells. Biochem Soc Trans. 2007;35(Pt 5):1208-1210. [4]. Glucose-dependent modulation of insulin secretion and intracellular calcium ions by GKA50, a glucokinase activator. Diabetes. 2007;56(6):1694-1702. |

Solubility Data

| Solubility (In Vitro) | DMSO :~46 mg/mL (~98.08 mM) |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 2.1322 mL | 10.6608 mL | 21.3215 mL | |

| 5 mM | 0.4264 mL | 2.1322 mL | 4.2643 mL | |

| 10 mM | 0.2132 mL | 1.0661 mL | 2.1322 mL |