Physicochemical Properties

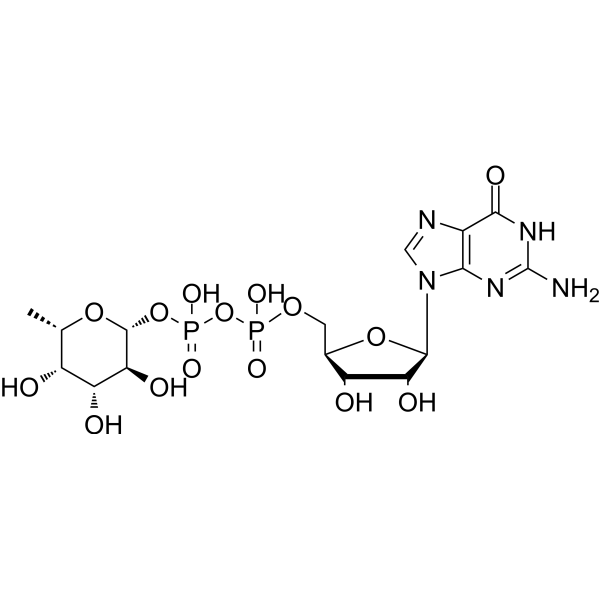

| Molecular Formula | C16H25N5O15P2 |

| Molecular Weight | 589.34 |

| Exact Mass | 589.082 |

| CAS # | 15839-70-0 |

| Related CAS # | GDP-L-fucose disodium;148296-47-3 |

| PubChem CID | 135412609 |

| Appearance | White to off-white solid powder |

| Density | 2.4±0.1 g/cm3 |

| Boiling Point | 1006.6ºC at 760 mmHg |

| Flash Point | 562.6ºC |

| Vapour Pressure | 0mmHg at 25°C |

| Index of Refraction | 1.869 |

| LogP | -2.95 |

| Hydrogen Bond Donor Count | 9 |

| Hydrogen Bond Acceptor Count | 17 |

| Rotatable Bond Count | 8 |

| Heavy Atom Count | 38 |

| Complexity | 1040 |

| Defined Atom Stereocenter Count | 8 |

| SMILES | C[C@H]1[C@H]([C@H]([C@@H](C(O1)OP(=O)(O)OP(=O)(O)OC[C@@H]2[C@H]([C@H]([C@@H](O2)N3C=NC4=C3N=C(NC4=O)N)O)O)O)O)O |

| InChi Key | LQEBEXMHBLQMDB-QIXZNPMTSA-N |

| InChi Code | InChI=1S/C16H25N5O15P2/c1-4-7(22)9(24)11(26)15(33-4)35-38(30,31)36-37(28,29)32-2-5-8(23)10(25)14(34-5)21-3-18-6-12(21)19-16(17)20-13(6)27/h3-5,7-11,14-15,22-26H,2H2,1H3,(H,28,29)(H,30,31)(H3,17,19,20,27)/t4-,5+,7+,8+,9+,10+,11-,14+,15?/m0/s1 |

| Chemical Name | [[(2R,3S,4R,5R)-5-(2-amino-6-oxo-1H-purin-9-yl)-3,4-dihydroxyoxolan-2-yl]methoxy-hydroxyphosphoryl] [(3S,4R,5S,6S)-3,4,5-trihydroxy-6-methyloxan-2-yl] hydrogen phosphate |

| Synonyms | GDP-L-fucose; GDP-fucose; guanosine diphosphate fucose; CHEBI:17009; (6-deoxy-beta-l-galactopyranosyl) ester; 15839-70-0; guanosine 5'-[3-(6-deoxy-L-galactopyranosyl) dihydrogen diphosphate]; [(2R,3S,4R,5R)-5-(2-amino-6-oxo-3H-purin-9-yl)-3,4-dihydroxyoxolan-2-yl]methyl [hydroxy-[(3S,4R,5S,6S)-3,4,5-trihydroxy-6-methyloxan-2-yl]oxyphosphoryl] hydrogen phosphate; |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month Note: This product requires protection from light (avoid light exposure) during transportation and storage. |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | Human Endogenous Metabolite |

| Enzyme Assay | The study established a cell-free enzymatic cascade for synthesizing GDP-L-fucose from mannose. The reaction involved six enzymes: mannose kinase (MK), phosphomannomutase (PMM), mannose-1-phosphate guanylyltransferase (MPG), GDP-mannose 4,6-dehydratase (GMD), GDP-4-keto-6-deoxymannose 3,5-epimerase (GMER), and GDP-4-keto-6-deoxymannose reductase (fSDR). Reactions were performed at 30°C in Tris-HCl buffer (pH 8.0) containing 10 mM mannose, 10 mM ATP, 10 mM GTP, 10 mM MgCl₂, and 1 mM NADPH. Enzymes were added at optimized concentrations: MK (0.1 U/mL), PMM (0.1 U/mL), MPG (0.1 U/mL), GMD (0.1 U/mL), GMER (0.1 U/mL), and fSDR (0.2 U/mL). Samples were collected at intervals, heated to 95°C for 5 min to terminate reactions, and centrifuged. Supernatants were analyzed by HPLC using a CarboPac PA20 column with isocratic elution (150 mM NaOH) and pulsed amperometric detection. GDP-L-fucose yield was quantified against a standard curve. |

| References |

[1]. Cell-free enzymatic synthesis of GDP-L-fucose from mannose. AMB Express. 2019 May 27;9(1):74. |

| Additional Infomation |

GDP-L-fucose is a crucial nucleotide sugar for fucosylation in glycoconjugates. This study achieved a 92% molar yield of GDP-L-fucose from mannose via the cell-free enzymatic cascade. The optimized system produced 0.82 mM GDP-L-fucose within 5 hours, demonstrating efficiency for large-scale synthesis. GDP-L-fucose is a GDP-fucose in which the fucosyl residue has L-configuration. It is a conjugate acid of a GDP-L-fucose(2-). GDP-L-Fucose is a metabolite found in or produced by Escherichia coli (strain K12, MG1655). Guanosine diphosphate fucose has been reported in Homo sapiens with data available. A nucleoside diphosphate sugar formed from GDPmannose, which provides fucose for lipopolysaccharides of bacterial cell walls, and for blood group substances and other glycoproteins. |

Solubility Data

| Solubility (In Vitro) | H2O :~250 mg/mL (~424.20 mM) |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 1.6968 mL | 8.4841 mL | 16.9681 mL | |

| 5 mM | 0.3394 mL | 1.6968 mL | 3.3936 mL | |

| 10 mM | 0.1697 mL | 0.8484 mL | 1.6968 mL |