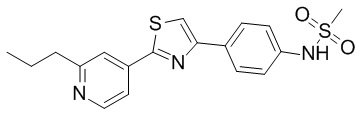

FGH10019 is a novel and potent inhibitor of the sterol regulatory element-binding protein (SREBP) with IC50 of 1 μM. It has high aqueous solubility and membrane permeability and may serve as a seed molecule for further development. Treatment of the CHO-K1 cells with analog FGH10019 decreases the percentage of the mature form of SREBP-2 (68 kDa) at lower concentrations than treatment with fatostatin.

Physicochemical Properties

| Molecular Formula | C₁₈H₁₉N₃O₂S₂ |

| Molecular Weight | 373.49 |

| Exact Mass | 373.091 |

| CAS # | 1046045-61-7 |

| PubChem CID | 25012898 |

| Appearance | Light yellow to khaki solid powder |

| Density | 1.3±0.1 g/cm3 |

| Boiling Point | 578.4±60.0 °C at 760 mmHg |

| Flash Point | 303.6±32.9 °C |

| Vapour Pressure | 0.0±1.6 mmHg at 25°C |

| Index of Refraction | 1.624 |

| LogP | 3.97 |

| Hydrogen Bond Donor Count | 1 |

| Hydrogen Bond Acceptor Count | 6 |

| Rotatable Bond Count | 6 |

| Heavy Atom Count | 25 |

| Complexity | 515 |

| Defined Atom Stereocenter Count | 0 |

| InChi Key | OWAXXHRQPWGNTG-UHFFFAOYSA-N |

| InChi Code | InChI=1S/C18H19N3O2S2/c1-3-4-16-11-14(9-10-19-16)18-20-17(12-24-18)13-5-7-15(8-6-13)21-25(2,22)23/h5-12,21H,3-4H2,1-2H3 |

| Chemical Name | N-[4-[2-(2-propylpyridin-4-yl)-1,3-thiazol-4-yl]phenyl]methanesulfonamide |

| Synonyms | FGH-10019FGH 10019FGH10019 |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| ln Vitro | The proportion of the mature form of SREBP-2 (68 kDa) in CHO-K1 cells was lowered to a lower concentration by treatment with the analog FGH10019 than by treatment with fatostatin. The IC50 of analogue FGH10019 was approximately 1 μM, which was 5–10 times lower than the IC50 of fatostatin (roughly 10 μM), according to densitometric examination of the gel [1]. |

| ln Vivo | Male ob/ob mice aged 5 weeks were fed FGH10019-treated chow at a dose rate calculated to provide approximately 23 mg/kg body weight of approximately 0.7 mg analog FGH10019 per day, with an average body weight of about 30 g. In comparison to control mice, the mice's body weight dropped by 8–9% after 8 weeks on a diet treated with analog 24 [1]. |

| References |

[1]. Synthesis and evaluation of diarylthiazole derivatives that inhibit activation of sterol regulatory element-binding proteins. J Med Chem. 2011 Jul 14;54(13):4923-7. |

Solubility Data

| Solubility (In Vitro) | DMSO : ≥ 38 mg/mL (~101.74 mM) |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 2.6774 mL | 13.3872 mL | 26.7745 mL | |

| 5 mM | 0.5355 mL | 2.6774 mL | 5.3549 mL | |

| 10 mM | 0.2677 mL | 1.3387 mL | 2.6774 mL |