Physicochemical Properties

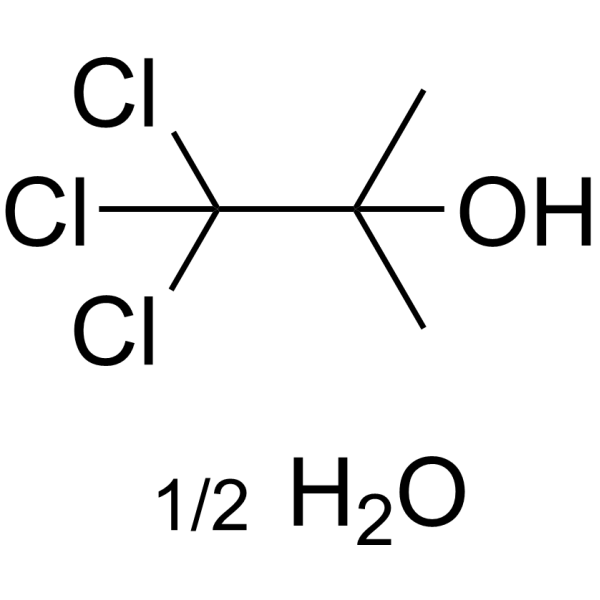

| Molecular Formula | C4H7CL3O.1/2H2O |

| Molecular Weight | 186.46 |

| Exact Mass | 369.923 |

| CAS # | 6001-64-5 |

| Related CAS # | Chlorobutanol;57-15-8 |

| PubChem CID | 5284505 |

| Appearance | White to yellow solid powder |

| Boiling Point | 167ºC |

| Melting Point | 75-79ºC |

| Flash Point | 100ºC |

| LogP | 2.063 |

| Hydrogen Bond Donor Count | 3 |

| Hydrogen Bond Acceptor Count | 3 |

| Rotatable Bond Count | 0 |

| Heavy Atom Count | 17 |

| Complexity | 83.8 |

| Defined Atom Stereocenter Count | 0 |

| SMILES | ClC(C(C([H])([H])[H])(C([H])([H])[H])O[H])(Cl)Cl |

| InChi Key | WRWLCXJYIMRJIN-UHFFFAOYSA-N |

| InChi Code | InChI=1S/2C4H7Cl3O.H2O/c2*1-3(2,8)4(5,6)7;/h2*8H,1-2H3;1H2 |

| Chemical Name | 1,1,1-trichloro-2-methylpropan-2-ol;hydrate |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| References |

[1]. Smoak IW, et al. Chlorobutanol: maternal serum levels and placental transfer in the mouse. Vet Hum Toxicol. 1997 Oct;39(5):287-90. [2]. Friesen WT, et al. The antibacterial stability of chlorobutanol stored in polyethylene bottles. Am J Hosp Pharm. 1971 Jul;28(7):507-12. |

Solubility Data

| Solubility (In Vitro) | DMSO : 100 mg/mL (536.31 mM) |

| Solubility (In Vivo) |

Solubility in Formulation 1: ≥ 2.5 mg/mL (13.41 mM) (saturation unknown) in 10% DMSO + 40% PEG300 + 5% Tween80 + 45% Saline (add these co-solvents sequentially from left to right, and one by one), clear solution. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 25.0 mg/mL clear DMSO stock solution to 400 μL PEG300 and mix evenly; then add 50 μL Tween-80 to the above solution and mix evenly; then add 450 μL normal saline to adjust the volume to 1 mL. Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH₂ O to obtain a clear solution. Solubility in Formulation 2: ≥ 2.5 mg/mL (13.41 mM) (saturation unknown) in 10% DMSO + 90% (20% SBE-β-CD in Saline) (add these co-solvents sequentially from left to right, and one by one), clear solution. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 25.0 mg/mL clear DMSO stock solution to 900 μL of 20% SBE-β-CD physiological saline solution and mix evenly. Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Solubility in Formulation 3: ≥ 2.5 mg/mL (13.41 mM) (saturation unknown) in 10% DMSO + 90% Corn Oil (add these co-solvents sequentially from left to right, and one by one), clear solution. For example, if 1 mL of working solution is to be prepared, you can add 100 μL of 25.0 mg/mL clear DMSO stock solution to 900 μL of corn oil and mix evenly. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 5.3631 mL | 26.8154 mL | 53.6308 mL | |

| 5 mM | 1.0726 mL | 5.3631 mL | 10.7262 mL | |

| 10 mM | 0.5363 mL | 2.6815 mL | 5.3631 mL |