Physicochemical Properties

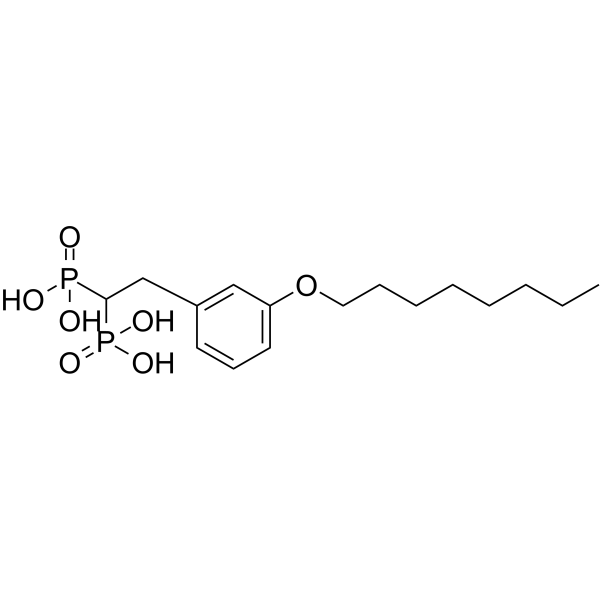

| Molecular Formula | C16H28O7P2 |

| Molecular Weight | 394.336847305298 |

| Exact Mass | 394.131 |

| CAS # | 2260887-57-6 |

| PubChem CID | 135220938 |

| Appearance | Off-white to light yellow solid powder |

| LogP | 2.1 |

| Hydrogen Bond Donor Count | 4 |

| Hydrogen Bond Acceptor Count | 7 |

| Rotatable Bond Count | 12 |

| Heavy Atom Count | 25 |

| Complexity | 437 |

| Defined Atom Stereocenter Count | 0 |

| SMILES | C(P(=O)(O)O)(P(=O)(O)O)CC1=CC=CC(OCCCCCCCC)=C1 |

| InChi Key | PHLMZTHHBLJPRI-UHFFFAOYSA-N |

| InChi Code | InChI=1S/C16H28O7P2/c1-2-3-4-5-6-7-11-23-15-10-8-9-14(12-15)13-16(24(17,18)19)25(20,21)22/h8-10,12,16H,2-7,11,13H2,1H3,(H2,17,18,19)(H2,20,21,22) |

| Chemical Name | [2-(3-octoxyphenyl)-1-phosphonoethyl]phosphonic acid |

| Synonyms | TH-Z145; 2260887-57-6; SCHEMBL20377215; TH-Z154; |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | FPPS (IC50 = 210 nM) |

| ln Vitro | TH-Z145 (GGPPS IC50 = 210 nM) is a very lipophilic bisphosphonate that lacks the cationic center essential for FPPS inhibition and is thus a specific GGPPS inhibitor (FPPS IC50 >30 μM). Researchers also used a known cholesterol-lowering agent (BPH-652) (Figure 2B) to specifically inhibit squalene synthase (SQS) (Liu et al., 2008). The use of HMG-CoA reductase, FPPS, SQS, as well as GGPPS inhibitors enables a determination of the biochemical basis for adjuvanticity. Chemical inhibition of SQS did not induce any adjuvant effect (Figure 2C), precluding the involvement of squalene or any of its downstream metabolites (e.g., cholesterol, steroids) in adjuvanticity [1]. |

| ln Vivo | In a pathogenic influenza model, TH-Z145 (20 μg, ip) shows significant preventive effects[1]. |

| Enzyme Assay |

Human FPPS/GGPPS inhibition assay and crystallization of human FPPS with TH-Z93 [1] Human FPPS and GGPPS were expressed, purified, and used for enzymatic inhibition assays as previously described (Zhang et al., 2009). Co-crystallization of human FPPS with TH-Z93 was carried out as follows. 20 mg/mL HsFPPS was mixed with 1 mM TH-Z93 and 2 mM MgCl2. The mixture was then incubated at 4°C overnight. The mixture was centrifuged and any precipitate discarded. The protein solution was then mixed with mother liquor (1.2 M Na/K phosphate, pH 5.2 and S10 25% glycerol) in a ratio of 1:1. Hanging drops were incubated at 18°C. Large, hexagon-like crystals appeared in 1-3 days and grew to maximum size in one week. The crystals were mounted, then frozen in liquid nitrogen. Diffraction data was collected at the Shanghai Synchrotron Radiation Facility (SSRF). Data was processed by using HKL2000 (Otwinowski and Minor, 1997) and refined by using Refmac5 (Murshudov et al., 2011) and Coot7 (Emsley and Cowtan, 2004). Refinement statistics are shown in Table S1. Graphics were created by using PyMOL (http://pymol.sourceforge.net/). |

| Cell Assay |

T cell activation and proliferation assays [1] CD4+ and CD8+ T cells were purified from OT-I or OT-II transgenic mice spleens using αCD4 or αCD8-microbeads, as per the manufacturer’s instructions, then were labeled with carboxyfluorescein succinimidyl amino ester (CFSE). For antigenic stimulation, a total of 5 × 104 purified T cells and 5 × 104 DCs (pretreated with 1 μM simvastatin for 24 h and then washed) pulsed with OVA (100 μg/mL) were mixed in each well of a 96-well plate, in triplicate, for 72 h at 37°C. Supernatant IFN-γ was measured by using mouse IFN-γ ELISA kit. DLN cell re-stimulation and proliferation [1] C57BL/6 mice were vaccinated on day 0 and boosted on day 14 and day 21. On day 28, 2 × 105 DLN cells were cultured in the presence or absence of antigen (100 μg/mL) for 72 h in 96-well plates (200 μL per well). Cells were pulsed with 1 μCi of [3H] thymidine (Perkin-Elmer) per well for the last 12 h of incubation. Data are expressed as counts per minute (c.p.m.). Cytokine profiling was performed on supernatants 72 h after antigen-restimulation using a CBA assay kit, according to the manufacturer’s instructions. |

| Animal Protocol |

Animal/Disease Models: B16-OVA cells (sc) xenograft mice model[1]. Doses: 20 μg Route of Administration: intraperitoneal (ip)injection Experimental Results: Inhibited tumor growth and prolonged survival. Therapeutic cancer vaccination [1] C57BL/6 mice were inoculated subcutaneously on the right hind flank with 3 × 105 B16-OVA cells. Tumors were allowed to establish for 5 days before treatment. Tumor-bearing mice were randomized into groups and vaccinated on day 5, 12 and 19 with one of: 100 μg of OVA, combined with 20 μg simvastatin; 20 μg TH-Z93; 20 μg TH-Z145 or 20 μg CpG. For the PD-1 blockade experiments, a-PD-1 (Bioxcell) (100 μg per mouse per injection) was injected intra-peritoneally, twice a week, after vaccination. For TC-1 tumors, C57BL/6 mice were inoculated subcutaneously on the right hind flank with 3 × 105 TC-1 cells (a murine lung epithelial line transformed with human papillomavirus 16 (HPV-16) E6/E7). Tumors were allowed to establish for seven days before treatment. Tumor-bearing mice were randomized into groups and treated on days 7, 14, and 21 (20 μg of E7, combined with 20 μg simvastatin; 20 μg TH-Z93; 20 μg TH-Z145 or 20 μg CpG). The PD-1 blockade experiments were performed as described above. For the TC-1 re-challenge model, mice were analyzed for the presence of tumors and survival on day 50 after tumor cell inoculation. One hundred days after the first round of tumor cell inoculation, mice were re-challenged with 3 × 105 TC-1 tumor cells. |

| References |

[1]. The Mevalonate Pathway Is a Druggable Target for Vaccine Adjuvant Discovery. Cell. 2018 Nov 1;175(4):1059-1073.e21. |

| Additional Infomation | Motivated by the clinical observation that interruption of the mevalonate pathway stimulates immune responses, we hypothesized that this pathway may function as a druggable target for vaccine adjuvant discovery. We found that lipophilic statin drugs and rationally designed bisphosphonates that target three distinct enzymes in the mevalonate pathway have potent adjuvant activities in mice and cynomolgus monkeys. These inhibitors function independently of conventional “danger sensing.” Instead, they inhibit the geranylgeranylation of small GTPases, including Rab5 in antigen-presenting cells, resulting in arrested endosomal maturation, prolonged antigen retention, enhanced antigen presentation, and T cell activation. Additionally, inhibiting the mevalonate pathway enhances antigen-specific anti-tumor immunity, inducing both Th1 and cytolytic T cell responses. As demonstrated in multiple mouse cancer models, the mevalonate pathway inhibitors are robust for cancer vaccinations and synergize with anti-PD-1 antibodies. Our research thus defines the mevalonate pathway as a druggable target for vaccine adjuvants and cancer immunotherapies.[1] |

Solubility Data

| Solubility (In Vitro) | DMSO : 100 mg/mL (253.59 mM) |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 2.5359 mL | 12.6794 mL | 25.3588 mL | |

| 5 mM | 0.5072 mL | 2.5359 mL | 5.0718 mL | |

| 10 mM | 0.2536 mL | 1.2679 mL | 2.5359 mL |