Physicochemical Properties

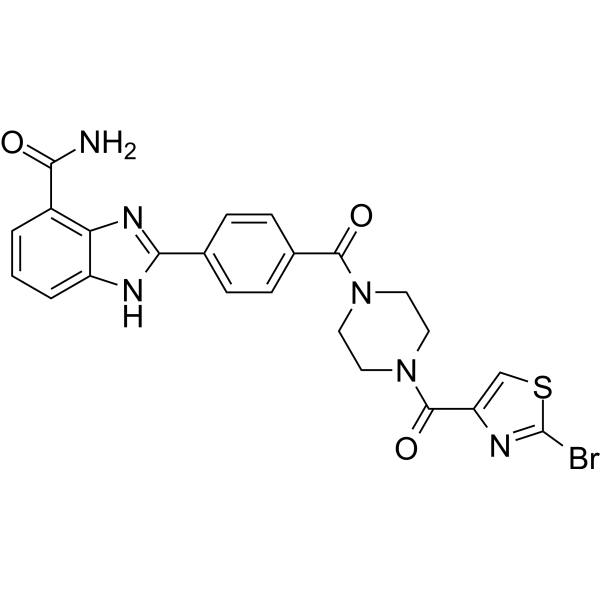

| Molecular Formula | C23H19BRN6O3S |

| Molecular Weight | 539.40 |

| CAS # | 2659357-95-4 |

| Appearance | Typically exists as solid at room temperature |

| HS Tariff Code | 2934.99.9001 |

| Storage |

Powder-20°C 3 years 4°C 2 years In solvent -80°C 6 months -20°C 1 month |

| Shipping Condition | Room temperature (This product is stable at ambient temperature for a few days during ordinary shipping and time spent in Customs) |

Biological Activity

| Targets | PARP1 4.62 nM (IC50) |

| ln Vitro | PARPi have been explored and applied in the treatment of various cancers with remarkable efficacy, especially BRCA1/2 mutated ovarian, breast, prostate, and pancreatic cancers. However, PARPi renders inevitable drug resistance and showed high toxicity because of PARP-Trapping with long-term clinic tracking. To overcome the drug resistance and the high toxicity of PARPi, many novel methods have been developed including PROTACs. Being an event-driven technology, PROTACs needs a high affinity, low toxicity warhead with no steric hindrance in binding process. Veliparib shows the lowest PARP-Trapping effect but could hardly to be the warhead of PROTACs because of the strong steric hindrance. Other PARP1 inhibitors showed less steric hindrance but owns high PARP-Trapping effect. Thus, the development of novel warhead with high PARP1 affinity, low PARP1-Trapping, and no steric hindrance would be valuable. In this work, we reserved benzimidazole as the motif to reserve the low PARP1-Trapping effect and substituted the pyrrole by aromatic ring to avoiding the steric hindrance in PARP1 binding cave. Thus, a series of benzimidazole derivates were designed and synthesized, and some biological activities in vitro were evaluated including the inhibition for PARP1 enzyme and the PARP-Trapping effect using MDA-MB-436 cell line. Results showed that the compound 19A10 has higher PARP1 affinity(IC50 = 4.62 nM)) and similar low PARP-Trapping effect compared with Veliparib(IC50 (MDA-MB-436) >100 μM). Docking study showed that the compound 19A10 could avoiding the steric hindrance which was much better than Veliparib. So, the compound 19A10 could potentially be a perfect warhead for PARP1 degraders. Besides, because of the depletion of the PARP1 and the decreasing of the binding capability, we suppose that the PROTACs using 19A10 as the warhead would be no-PARP-Trapping effect. Furthermore, QSAR study showed that to develop novel compounds with high PARP1 binding affinity and low PARP-Trapping, we can choose the skeleton with substituent R1H, R2 = piperiazine, and R3 with large tPSA. And, if we want to develop the compounds with high PARP1 binding affinity and high PARP-Trapping which can possibly improve the lethality against tumor cells, we can choose the skeleton with substituent R1F, R2 = 3-methy-piperiazine, and R3 with large tPSA[1]. |

| References |

[1]. High affinity and low PARP-trapping benzimidazole derivatives as a potential warhead for PARP1 degraders. Eur J Med Chem. 2024 May 5:271:116405. |

Solubility Data

| Solubility (In Vitro) | May dissolve in DMSO (in most cases), if not, try other solvents such as H2O, Ethanol, or DMF with a minute amount of products to avoid loss of samples |

| Solubility (In Vivo) |

Note: Listed below are some common formulations that may be used to formulate products with low water solubility (e.g. < 1 mg/mL), you may test these formulations using a minute amount of products to avoid loss of samples. Injection Formulations (e.g. IP/IV/IM/SC) Injection Formulation 1: DMSO : Tween 80: Saline = 10 : 5 : 85 (i.e. 100 μL DMSO stock solution → 50 μL Tween 80 → 850 μL Saline) *Preparation of saline: Dissolve 0.9 g of sodium chloride in 100 mL ddH ₂ O to obtain a clear solution. Injection Formulation 2: DMSO : PEG300 :Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL DMSO → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Injection Formulation 3: DMSO : Corn oil = 10 : 90 (i.e. 100 μL DMSO → 900 μL Corn oil) Example: Take the Injection Formulation 3 (DMSO : Corn oil = 10 : 90) as an example, if 1 mL of 2.5 mg/mL working solution is to be prepared, you can take 100 μL 25 mg/mL DMSO stock solution and add to 900 μL corn oil, mix well to obtain a clear or suspension solution (2.5 mg/mL, ready for use in animals). Injection Formulation 4: DMSO : 20% SBE-β-CD in saline = 10 : 90 [i.e. 100 μL DMSO → 900 μL (20% SBE-β-CD in saline)] *Preparation of 20% SBE-β-CD in Saline (4°C,1 week): Dissolve 2 g SBE-β-CD in 10 mL saline to obtain a clear solution. Injection Formulation 5: 2-Hydroxypropyl-β-cyclodextrin : Saline = 50 : 50 (i.e. 500 μL 2-Hydroxypropyl-β-cyclodextrin → 500 μL Saline) Injection Formulation 6: DMSO : PEG300 : castor oil : Saline = 5 : 10 : 20 : 65 (i.e. 50 μL DMSO → 100 μLPEG300 → 200 μL castor oil → 650 μL Saline) Injection Formulation 7: Ethanol : Cremophor : Saline = 10: 10 : 80 (i.e. 100 μL Ethanol → 100 μL Cremophor → 800 μL Saline) Injection Formulation 8: Dissolve in Cremophor/Ethanol (50 : 50), then diluted by Saline Injection Formulation 9: EtOH : Corn oil = 10 : 90 (i.e. 100 μL EtOH → 900 μL Corn oil) Injection Formulation 10: EtOH : PEG300:Tween 80 : Saline = 10 : 40 : 5 : 45 (i.e. 100 μL EtOH → 400 μLPEG300 → 50 μL Tween 80 → 450 μL Saline) Oral Formulations Oral Formulation 1: Suspend in 0.5% CMC Na (carboxymethylcellulose sodium) Oral Formulation 2: Suspend in 0.5% Carboxymethyl cellulose Example: Take the Oral Formulation 1 (Suspend in 0.5% CMC Na) as an example, if 100 mL of 2.5 mg/mL working solution is to be prepared, you can first prepare 0.5% CMC Na solution by measuring 0.5 g CMC Na and dissolve it in 100 mL ddH2O to obtain a clear solution; then add 250 mg of the product to 100 mL 0.5% CMC Na solution, to make the suspension solution (2.5 mg/mL, ready for use in animals). Oral Formulation 3: Dissolved in PEG400 Oral Formulation 4: Suspend in 0.2% Carboxymethyl cellulose Oral Formulation 5: Dissolve in 0.25% Tween 80 and 0.5% Carboxymethyl cellulose Oral Formulation 6: Mixing with food powders Note: Please be aware that the above formulations are for reference only. InvivoChem strongly recommends customers to read literature methods/protocols carefully before determining which formulation you should use for in vivo studies, as different compounds have different solubility properties and have to be formulated differently. (Please use freshly prepared in vivo formulations for optimal results.) |

| Preparing Stock Solutions | 1 mg | 5 mg | 10 mg | |

| 1 mM | 1.8539 mL | 9.2696 mL | 18.5391 mL | |

| 5 mM | 0.3708 mL | 1.8539 mL | 3.7078 mL | |

| 10 mM | 0.1854 mL | 0.9270 mL | 1.8539 mL |